CD Automation offers advanced power controllers ideal for the wood industry. In fact, these instruments are designed to optimize the drying, coating and curing processes of coatings, reducing processing times and increasing the sustainability of processing.

Wood Drying and Paint Curing with Short Wave Infrared emitters (IRSW)

In a context of drying materials, such as wood, it is necessary to remove internal moisture without overheating the surface. Excessive surface heat can cause blistering or filming of glues and inks, where the top layer appears dry but remains moist inside. To avoid these problems, it is preferable to use short-wave infrared lamps (IRSW), as they allow greater penetration of heat energy deep down, preventing it from being retained only on the surface and improving the efficiency of the drying process.

Among CD Automation’s products, the REVO S and REVO C system are particularly suitable for controlling IRSW lamps.

Gluing of details and edges with short-wave infrared lamps (single-phase IRSW):

CD Automation’s proposals

Single-phase infrared shortwave lamps (IRSWs) are an advanced technology for gluing details and edges in the wood industry. CD Automation offers solutions such as the REVO S and REVEX power controllers, designed to optimize the efficiency of these processes. These controllers enable highly accurate management of the thermal energy transmitted by IRSW lamps, ensuring uniform and rapid heating. Accurate power control reduces the risk of overheating, preventing defects in materials and ensuring strong and uniform bonding. These solutions improve energy efficiency and overall quality, optimizing processing time and ensuring long-lasting results.

REVEX: power controller technical characteristics

- REVEX is a scalable product with flexible configurations down to small sizes.

- Compact unit with built-in fuses and integrated current transformer.

- Digital inputs useful for Enable function.

- Serial input useful for acquiring data for diagnostics and maintenance.

- Suitable for all applications.

- Integrated field bus for communication with leading PLCs on the market.

- Excellent value for money, ability to select different hardware and software options as needed. You buy only what you need.

REVO S: technical characteristics of solid state relays

- High-performance, reliable, flexible and compact solid-state relays available in sizes from 3.5A to 800A.

- Management of single-phase and three-phase electric heaters.

- Approved SCCR 100kA – 600V (Short Circuit Current Rating), according to UL508.

- Approved CE / cUL / EAC.

- Integrated fuse and current transformer: take up less space in the cabinet, can be mounted side by side; easy replacement of fuses.

- Heater Break (HB) alarm to diagnose partial or total load break or thyristor short circuit. Simple alarm calibration from the front keypad.

- Easy to manage; above 60A, the handy keypad is available to quickly change the input and set diagnostics when present.

- SSR or Analog input already configured, editable from front button.

Wood finishing with UV lamps

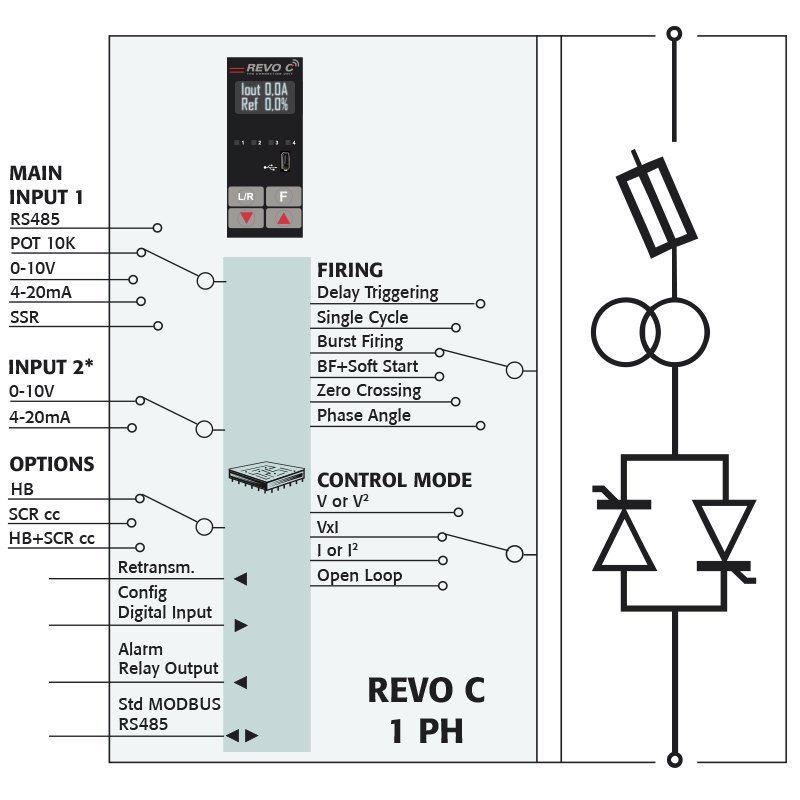

CD Automation has developed the REVO C power controller for optimal management of UV lamps, ideal for applications such as printing and curing wood coatings.

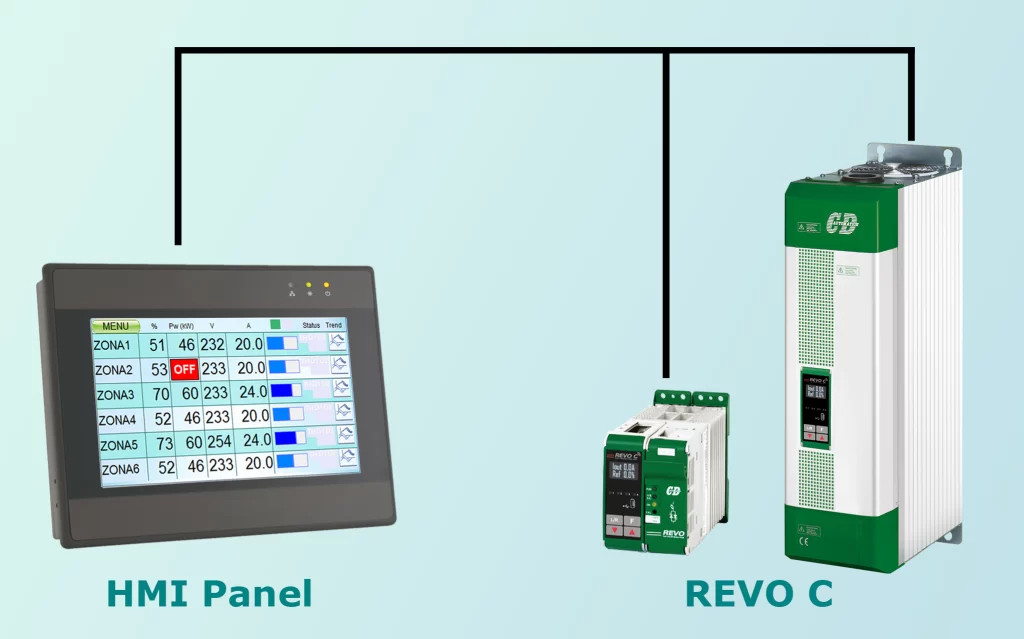

The REVO C communicates with a Touch HMI panel and adjusts power according to the presence of the material, reducing it to standby mode to save energy.

Using a sophisticated algorithm, it turns on lamps at a constant current, preventing unwanted shutdowns. Precise power regulation reduces energy consumption, lowering CO2 emissions, and offers efficient management of connected transformers.

Through a serial communication system or an analog input, the signal can be adjusted from 30% to 100%, depending on the type of lamp used.

In addition, REVO C is a digital Thyristor unit that significantly reduces the wiring needed. The panel also allows the implementation of custom software, with direct support from CD Automation to tailor the solution to the user’s specific needs.