In the glass industry, efficiency and precise control of production processes are essential to guarantee the quality of the end product. CD Automation offers advanced solutions with its power controllers, ideal for managing machinery along the entire glass production line. Using state-of-the-art technology, these thyristor units ensure optimal control of temperature and energy, critical elements in the glass manufacturing process.

CD Automation’s power controllers are designed to maintain a constant temperature in furnaces and glass-forming machines, compensating for fluctuations in mains voltage and thus improving energy efficiency. With CE and UL certifications, these units also offer advanced features such as load diagnostics, logic input and Zero Crossing ignition. The use of these power controllers enables greater process reliability and reduced operating costs, making CD Automation an ideal partner for the glass industry.

CD Automation’s power controllers for the glass industry

CD Automation offers a complete range of state-of-the-art power controllers, ideal for machinery management in the glass industry. The REVO PC, REVO PN, REVO C and REVEX product families have advanced technical features that optimise production efficiency and quality.

Typical Cycle for Glass Industry with Profinet/Ethernet IP/Modbus TCP communication

CD Automation’s SCR units offer advanced and reliable solutions for the Glass industry, optimising energy efficiency and ensuring precise control of electric heaters in demanding applications. Discover why these units are the ideal choice to improve the performance and safety of your industrial processes.

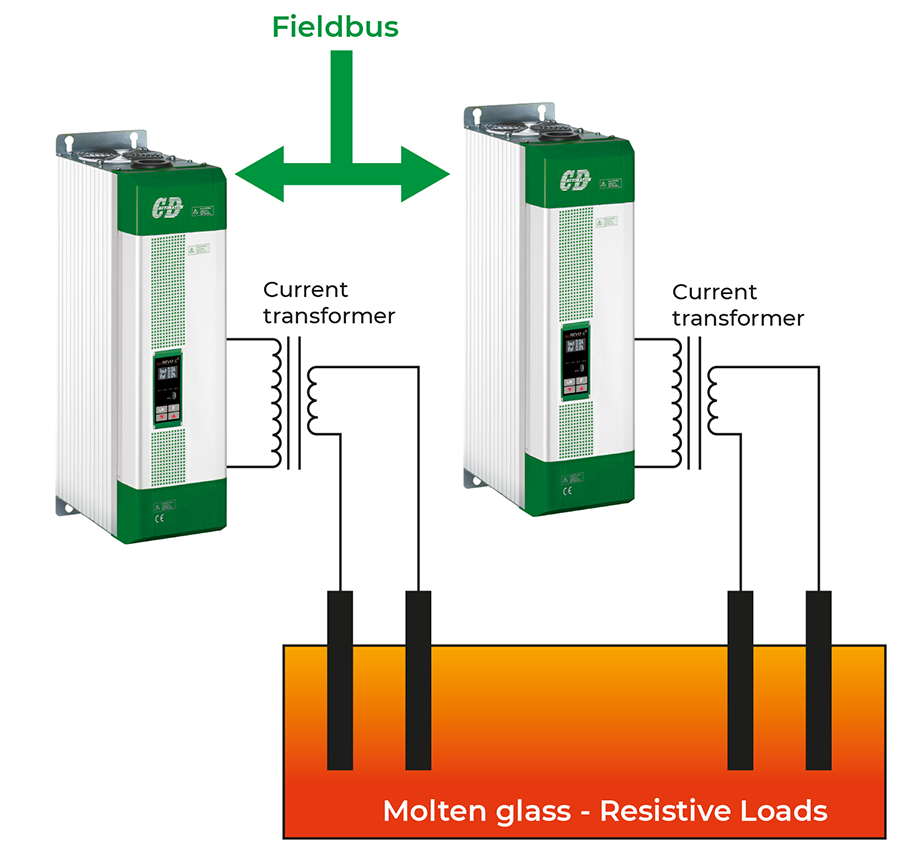

Typical systems can have between 30 and 35 zones, each one having a power range from 100 to 150 KW. CD Automation product normally used is REVO C-3PH.

Here on the side you can find an example of a controlled area via fieldbus. For each zone it is possible to have a dedicated terminal to be positioned in front of the panel, connected directly to the unit. In the event of an emergency it is possible to operate on the unit by setting its power in manual mode with prior knowledge of the password or enabling from the control room.

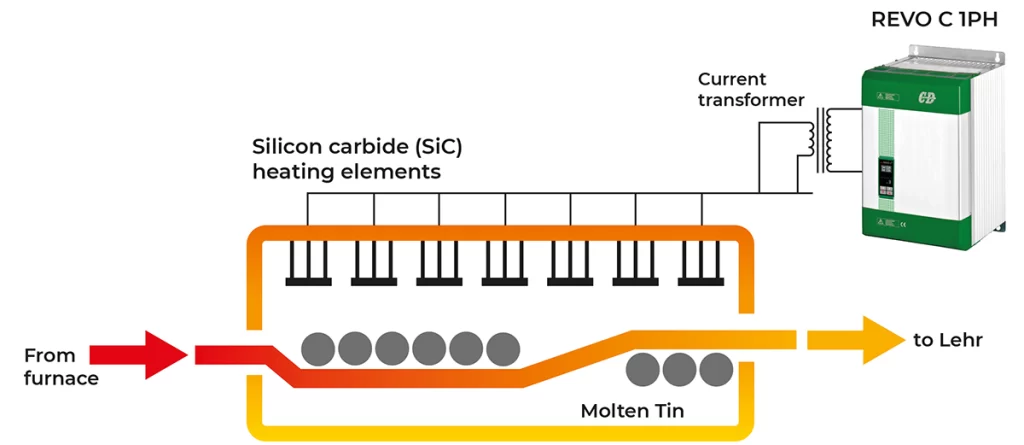

In the Tin Bath part the SiC silicon carbide elements are placed on the secondary of a transformer, while in the Annealing Lehr part it is a question of controlling normal three-phase connection resistances, in this case you can choose between the REVO C series and the REVO S 2PH.

In addition CD Automation can offer REVO PC. This powerful unit with its unique algorithm will minimize energy cost by controlling synchronisation and power limit of each zone. CD Automation can also supply product and specialist know how for the following applications in the Glass Industry:

- Boosting Power Control

- Tin Furnace Power Control

- Power Control of Continuous Annealing Furnace

Boosting

In the early stages of glass production, raw materials such as sand are heated and melted. Molten glass is a conductor of electricity, and the passage of high currents through it produces direct heating. This heating is advantageous because it heats the cooler lower glass in the furnace, causing a stirring effect that improves melting and heat transfer. Boosting is often used to manage periodic fluctuations in demand or to sustain the extraction rate towards the end of the furnace’s operating life. CD Automation’s power controllers are perfect for this application.

Float Bath

The molten tin bath is a crucial step in the production of flat glass. During this process, the glass is taken out of the furnace at a temperature of 1100°C and gradually cools down until it solidifies at 600°C. At this stage, the glass undergoes essential processes such as heating, fire polishing and controlled cooling. Precise temperature control is essential in modern flat glass production systems to effectively manage all zones, ensuring product quality and optimising consumption. CD Automation’s power controllers, such as the SCR REVO C units, are equipped with an optimisation algorithm specifically for SiC heaters, ensuring optimal thermal management.

Annealing lehr

In the glass production process, gradual cooling in annealing furnaces is essential to prevent breakage and deformation of the sheet. During this phase, the glass is brought to high but lower temperatures than during melting, using infrared or normal heating elements driven in Burst Firing. CD Automation’s REVO C 2PH power controllers are ideal for this application due to their ability to handle burst firing without the need for three-stage control. In addition, other firing methods can be used depending on the type of heating element. REVO PN or REVO PC + REVO C solutions are perfect for managing multiple zones and heating profiles, ensuring precise and optimised temperature control during the cooling phase of the glass.

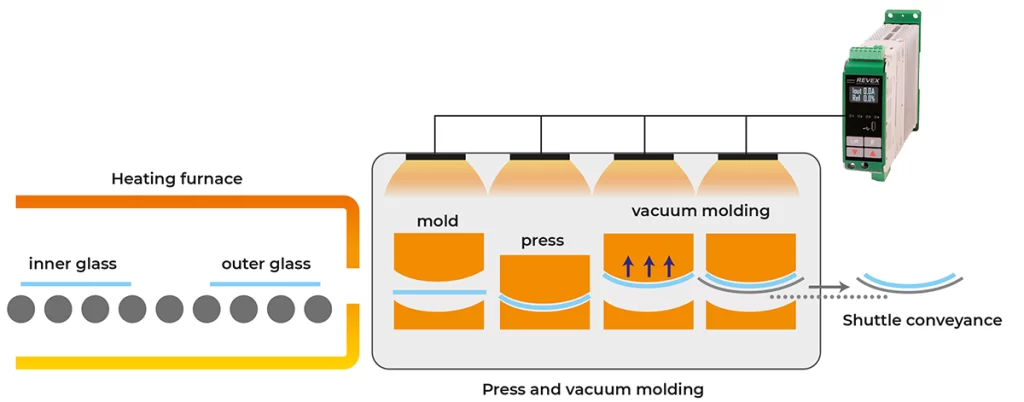

Laminating and bending plants

In the glass manufacturing industry, the lamination process is crucial for safety, as it combines several layers of glass with a plastic film. This ensures that, in the event of breakage of tempered glass, fragments remain attached to the film, minimising damage to people and property. This method is widely used in the production of windscreens, rear windows and car windows, and is often complemented by the processes of glass bending and screen printing.

In the bending process, the furnace is heated to temperatures between 650 and 750°C to make the glass viscous and allow it to adhere to a concave or convex mould. Subsequently, the glass is cooled while maintaining the desired shape. Normal heating elements are used for these processes, and high precision in power control is essential. For this stage of the work, CD Automation recommends the use of the REVEX, REVO C and REVO PN units, which offer extremely accurate power control, both in phase angle and single or half cycle firing. These power controllers ensure optimal temperature management, improving end-product quality and operating efficiency.

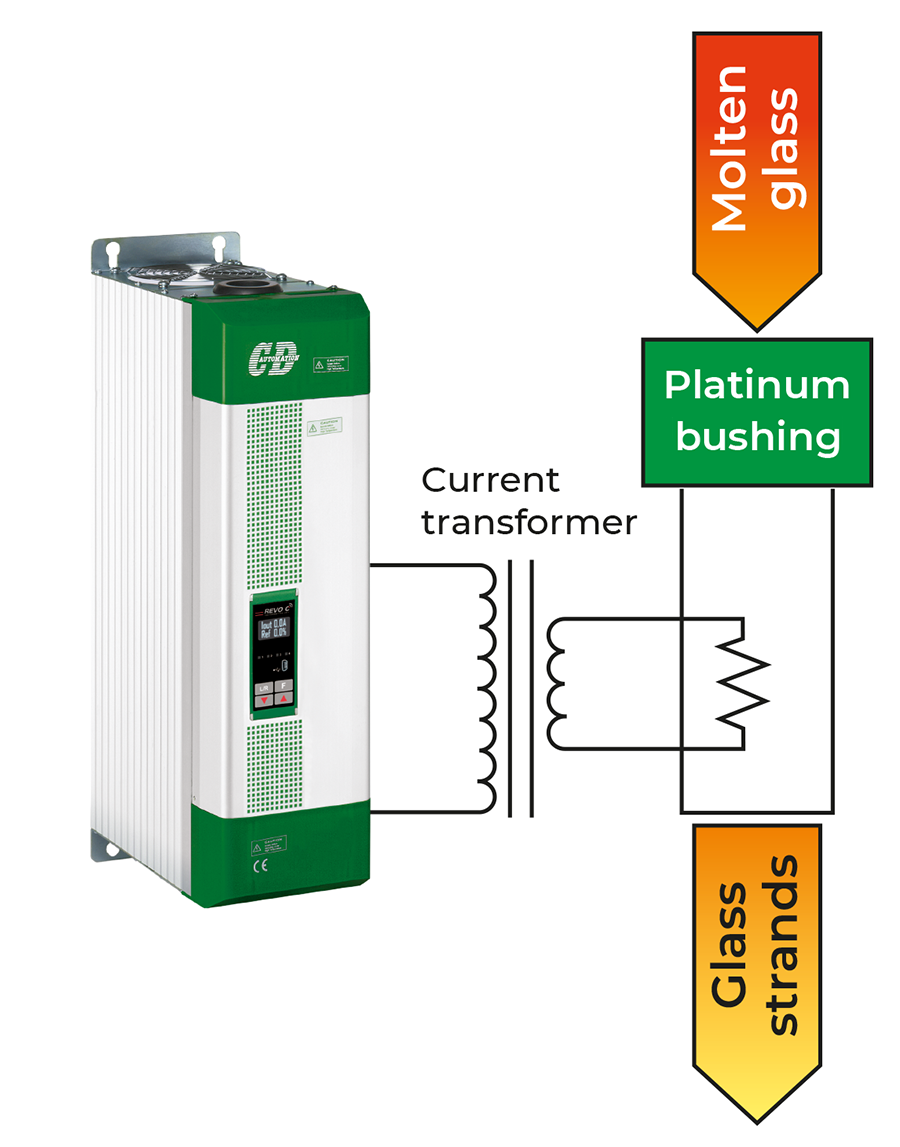

Bushing temperature control

The production of glass fibres requires a high level of precision and reliability to ensure a consistent quality of the fibre produced. Precise temperature control is essential for this application. CD Automation recommends the use of REVO C 1PH power controllers, available with units ranging from 800A up to 2100A. These power controllers ensure accurate and stable temperature control, which is essential for maintaining optimal conditions in the glass fibre production process. REVO C units also offer advanced configuration options, such as phase angle start ramp and the ability to handle inductive loads, ensuring high performance and consistent end-product quality.