SiC Elements:

In various industrial sectors, Silicon Carbide (SiC) resistors are a preferred choice due to their exceptional high temperature resistance properties and energy efficiency. CD Automation, a leader in power control technology innovation, introduces advanced solutions for the optimal management of SiC resistors, designed to maximise their lifetime and performance.

- Read more

Our range of power controllers is specifically developed to suit the unique characteristics of SiC elements, ensuring precise regulation and optimal energy management. Through the use of sophisticated technologies, CD Automation is able to offer systems that improve process reliability and reduce energy consumption, providing tailor-made solutions for even the most demanding customers. Rely on CD Automation for advanced management of your SiC resistors, and take your operational efficiency to the next level.

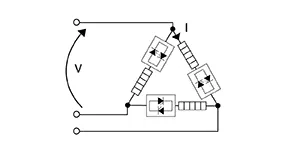

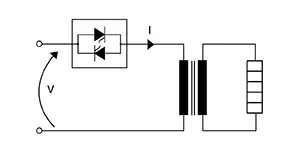

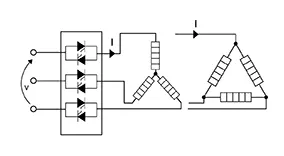

Silicon Carbide heating elements: select your load connection

Choosing the right connection for controlling Silicon Carbide resistors is crucial to ensure maximum system efficiency and reliability. CD Automation is dedicated to providing expert advice and customised solutions, ensuring perfect compatibility between SiC resistors and our advanced power controllers.

SiC heating elements: learn more about CD Automation solutions

In the field of high-efficiency heating systems, silicon carbide (SiC) heating elements stand out for their superior performance, and therefore require equally advanced power control solutions.

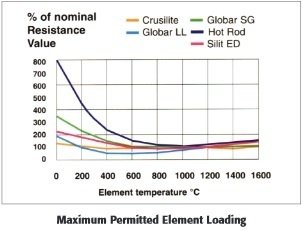

Silicon carbide is a semiconductor material with a much higher resistivity than metallic materials. The resistance value of these elements at room temperature is quite high, and decreases with increasing temperature to a minimum value of around 600-900°C; at element temperatures above 900°C, the increase in resistivity increases with increasing temperature, as shown in figure.

Silicon carbide (SiC) resistors show a change in their value with temperature and ageing, with the value at the end of their period of use becoming approximately 4 times the initial one.

For optimum handling of SiC resistors, constant power regulation with a VxI transfer feedback is required. On three-phase loads with Silicon Carbide, the use of a VxI feedback is suggested to achieve constant power regulation, necessary to compensate for changes in resistance value with temperature and age of the elements.

CD Automation, at the forefront of control technology, presents the REVEX 1PH and REVO C (1PH and 3PH) product lines specifically designed to optimise the use of SiC elements. These solutions combine precision, energy efficiency and reliability, meeting the needs of industrial applications that require maximum thermal control and optimal energy management.

REVEX 1PH: precision and versatility in the control of SiC elements

CD Automation’s REVEX 1PH is the ideal solution for precision control of silicon carbide (SiC) heating elements, combining advanced technology and configuration versatility. Designed for single-phase applications, this SSR features state-of-the-art technology that ensures precise power regulation, essential for thermal process optimisation and energy efficiency. Customised configuration capability allows users to tailor the device to the specific needs of the application, improving performance and reducing operating costs.

REVEX 1PH is a fully configurable single-phase power controller. If you don’t need features, you can remove them for an immediate cut in unit cost.

- 30A to 280A

- Input type: 4:20mA, 0:10Vdc, SSR

- Firing mode: Single cycle, Half Cycle, Burst Firing, Phase Angle, Delayed Triggering, different types of adjustable ramp

- Control mode: Voltage, Current and Power or V2 and I2 with additional Transfer to VxI

- Communication RS485 with Modbus® protocol as standard

- USB: Port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- Approvazioni: Conforme a CE+EMC, EAC

- Dual Current Limit: For peak and RMS value

REVO C 1PH and 3PH: advanced management for single-phase and three-phase SiC loads

CD Automation’s REVO C series represents excellence in power control for a wide range of industrial applications, including those using silicon carbide (SiC) heating elements. These advanced controllers are designed to provide flawless control in both single-phase and three-phase configurations, adapting to different load types with maximum efficiency and reliability. Characterised by robust construction and state-of-the-art technologies, REVO C controllers ensure precise power regulation, fast response to load variations and optimised energy management. The integration of advanced features such as serial communication and sophisticated voltage control allows REVO C controllers to offer superior performance, improving process quality and reducing operating costs.

REVO C 1PH: technical features

- Controlled phases: 1

- Current range from 30 to 2100A

- Voltage range 480V, 600V and 690V +/-10%

- Input: 0:20mA, 4:20mA, 0:10V, SSR and ModBus as std and different Field Bus

- Firing mode: Half Cycle, Single Cycle, Burst Firing, Delayed Triggering, Phase Angle with or without Soft Start

- USB: port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- 100 kA: Short Circuit Current Rating (SCCR) up to 600V

- Approvals CE+EMC; EAC; cUL from 30A to 700A, UL from 800A to 2100A

REVO C 3PH: technical features

- Controlled phases: 3

- Current range from 30 to 2100A

- Voltage range 480V, 600V and 690V +/-10%

- Input: 0:20mA, 4:20mA, 0:10V, SSR and ModBus as std and different Field Bus

- Firing mode: Burst Firing, Delayed Triggering and Phase Angle with or without Soft Start

- USB: port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- 100 kA: Short Circuit Current Rating (SCCR) up to 600V

- Approvals CE+EMC; EAC; cUL from 30A to 500A, UL from 600A to 2100A

SiC Touch Panel: the solution that facilitates the control of SiC heating elements

CD Automation has developed a series of tools to facilitate the implementation of applications requiring the control of Silicon Carbide (SiC) heating elements. The philosophy is to use a standard Thyristor Unit with serial communication and to implement the control strategy through a front control panel. This touch screen panel in addition to the universal CD Automation unit allows you to work with all firing and control modes, removing all the risks that could arise from selecting an unsuitable control type

This solution brings several advantages. Through an operator interface connected to our communication-equipped SCR units, the following benefits can be achieved:

- Automatic configuration and tuning of the thyristor unit

- Automatic tuning of Power Control mode VxI

- Message on the need to replace SiC elements because they are at the end of their life

- Automatic switch from Voltage to VxI control mode when the element temperature is the correct one

- Automatic tuning procedure of Heather break alarm to diagnostic partial or total load failure

- Diagnostic of fuse failure and Thyristor in short circuit

- Recent and Historical Curve of following process variable

- Power density W/cm2

- Load voltage

- Load current

- Power to the load

- Resistance value curve with new element

- Time elapsed from start to actual resistance value

Two different modes to drive SiC:

- Burst Firing with automatic adjustment of Power Limit

- Phase Angle with transfer from voltage to Power control mode

CD Automation has developed a series of tools to facilitate the implementation of applications requiring the control of Silicon Carbide (SiC) heating elements. The philosophy is to use a standard Thyristor Unit with serial communication and to implement the control strategy through a front control panel. This touch screen panel in addition to the universal CD Automation unit allows you to work with all firing and control modes, removing all the risks that could arise from selecting an unsuitable control type

This solution brings several advantages. Through an operator interface connected to our communication-equipped SCR units, the following benefits can be achieved:

- Automatic configuration and tuning of the thyristor unit

- Automatic tuning of Power Control mode VxI

- Message on the need to replace SiC elements because they are at the end of their life

- Automatic switch from Voltage to VxI control mode when the element temperature is the correct one

- Automatic tuning procedure of Heather break alarm to diagnostic partial or total load failure

- Diagnostic of fuse failure and Thyristor in short circuit

- Recent and Historical Curve of following process variable

- Power density W/cm2

- Load voltage

- Load current

- Power to the load

- Resistance value curve with new element

- Time elapsed from start to actual resistance value

Two different modes to drive SiC:

- Burst Firing with automatic adjustment of Power Limit

- Phase Angle with transfer from voltage to Power control mode

Learn more by watching the interview with Stefano Ramondetta, owner of CO.RAM srl, together with Simone Brizzi and Stefano Colombo, respectively CEO and R&D Director of CD Automation, where they discuss challenges, innovations and future prospects.