MoSi2 heating elements:

Molybdenum disilicide (MoSi2) heating elements are renowned for their excellent resistance to high temperatures and oxidation, making them ideal for high-temperature industrial applications. CD Automation addresses this need with state-of-the-art power control solutions, designed to optimise the efficiency and longevity of these critical components.

- Read more

Our advanced power controllers are specifically developed to ensure precise and reliable management of MoSi2 elements, improving overall system performance and reducing energy consumption. With innovative technologies and a focus on customisation, CD Automation is the ideal partner to raise the operational efficiency of your applications using MoSi2 heating elements.

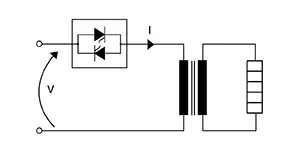

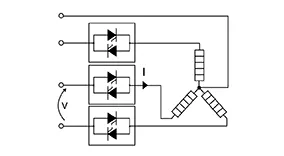

MoSi2 heating elements: select your load connection

Choosing the right connection for MoSi2 heating elements is crucial to maximising system efficiency and lifetime. CD Automation provides expert advice and customised solutions to ensure that each configuration is perfectly matched to the specific needs of your system.

Advanced management of heating elements with thermal variability: solutions for constant resistance and current limitation

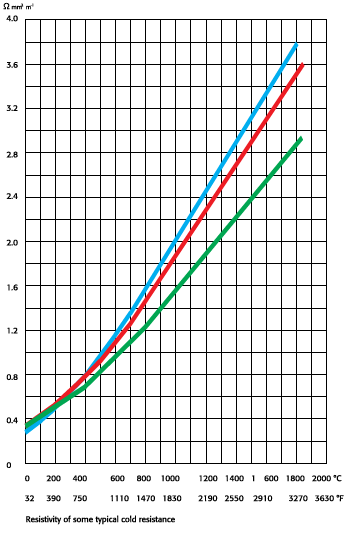

This type of heaters increase resistivity sharply with temperature but has no age-related changes. The graph show that at ambient temperature the resistance value is very low and increase its value up to 10 times.

The initial current at cold elements can be 16 times the rated current.

For this type of application, it is necessary to use units that allow a Phase Angle firing with Soft Start (3 sec.) and Current Limit.

When the resistance value reaches a set value, two types of working methods are possible, which can be selected from the HMI:

– Phase Angle plus Current Limit all the time or

– Phase Angle plus Current Limit when the resistor is cold and transfers to Delay Triggering if load is coupled with transformer

An example of MoSi2 heating elements are Kanthal Super (TM)* elements

*trademark of Sandvik Corporation

MoSi2 heating elements: learn more about CD Automation solutions

For efficient power and temperature control of MoSi2 heating elements, CD Automation offers the flagship solutions of the REVEX and REVO C lines. The REVEX products are ideal for single-phase applications, while the REVO C series is perfect for more complex single-phase and three-phase configurations. These solutions provide optimal power management and precise regulation, essential for maximising the efficiency and lifetime of MoSi2 heating elements in high temperature industrial environments. Discover how these advanced technologies can transform thermal management in your plant.

REVEX 1PH

CD Automation’s REVEX 1PH is a single-phase solid state relay designed for the precise control of MoSi2 heating elements and other high resistance loads. This device stands out for its reliability and its ability to effectively handle load variations, which are essential in demanding industrial environments. With advanced technology that allows fine adjustment of power, the REVEX 1PH ensures even heat distribution and reduces the risk of overheating. Its installation is simplified and its configurability makes it suitable for a wide range of applications, ensuring optimal performance and efficient energy management at all times.

- 30A to 280A

- Inputs: 4:20mA, 0:10V, SSR

- Firing mode: Single cycle, Half cycle, Burst, Phase Angle, Delayed Triggering, different types of adjustable ramp

- Control Mode: Voltage, Current and Power or V2 and I2 with additional Transfer to VxI

- Communication RS485 with Modbus® protocol standard

- USB: Port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- Approvals: CE+EMC, EAC

- Dual Current Limit: For peak and RMS value

REVO C 1PH and 3PH

CD Automation’s REVO C serie, in 1PH and 3PH versions, represents the ideal solution for advanced control of MoSi2 heating elements in various industrial environments. These power controllers are designed to offer precise and reliable control in both single-phase and three-phase configurations. Equipped with the ability to handle high currents and load variations, REVO C controllers ensure optimal power regulation and even heat distribution, thus improving operational efficiency and reducing energy consumption. Their robustness and versatility make them suitable for a wide range of industrial applications.

REVO C 1PH: technical features

- Controlled phases: 1

- Current Range from 30 to 2100A

- Voltage Range 480V, 600V e 690V +/-10%

- Inputs: 0:20 e 4:20mA, 0:10V, SSR and ModBus as standard and different Field Bus

- Firing mode: Half Cycle, Single Cycle, Burst Firing, Delayed Triggering, Phase Angle with or without Soft Start

- USB: port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- 100 kA: Short Circuit Current Rating (SCCR) up to 600V

- Approvals CE+EMC; EAC; cUL from 30A to 700A, UL from 800A to 2100A

REVO C 3PH: technical features

- Controlled phases: 3

- Current Range from 30 to 2100A

- Voltage Range 480V, 600V e 690V +/-10%

- Inputs: 0:20 e 4:20mA, 0:10V, SSR and ModBus as standard and different Field Bus

- Firing Mode: Burst Firing, Delayed Triggering and Phase Angle with or without Soft Start

- USB: port integrated for configuration in safety mode (No Load and Auxiliary Voltage needed) Unit Powered Through USB

- 100 kA: Short Circuit Current Rating (SCCR) up to 600V

- Approvals CE+EMC; EAC; cUL from 30A to 500A, UL from 600A to 2100A

Join us for an exclusive interview with Luigino Da Re and Angelo Scipione of CIEFFE Forni, where we explore the latest technological innovations in the electric oven sector. Find out how Industry 4.0 and new control strategies are revolutionising energy efficiency and sustainability.